In this article, we will explain the tasks each group has been doing everyday, which allowed for us to build a plastic boat.

Cords team

Which materials are we using to build our boats? Plastic bottles with defects, that couldn’t enter the market to be sold. And incredibly, there are lots of them!

The first thing to do is to cut the bottoms of the best bottles, which makes them fit into the manual stringing machine.

- Ivan with lots of joy…

- and the bottoms of the bottles are cut

The following video shows how the cords are then made (Marco is a really good worker), a simple and efficient procedure with a blade that cuts the entire bottle.

Net team

With 2 looms, this group is making nets with the plastic cords that come from the previous team. First, each loom has to be prepared with fixed horizontal cords layered in two levels. Then, the vertical cords are fixed between the two levels of horizontal cords. All stages of this part of the work are documented in the next videos.

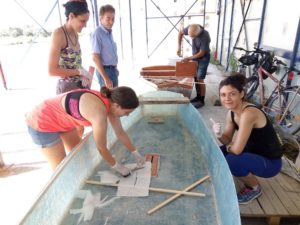

Polyester team

The plastic net is cut by the size of the mold, and then mixed with polyester liquid, so that it forms a layer to use on the boat. The fiber glass is added and glued with the liquid polyester and pressed with a piece of plywood to remove air bubbles.

- Cut the plastic net and fiber glass

- …by the size of the boat

- Josefine mix the polyester and the hardner

- Francesca applies the mixture on the layers

- Josefine and Anamarija waxing the wood

- Pressure to fix the layers

And after everything dries…

- Did you know boats have a hole in the middle?

- And then a box around the hole?

- Last details – sanding, polyester, fiber glass,…

- Almost ready… Starting the party.

- And the boat is ready, after 2 weeks of work!

- The name of the boat is Piratiki

By Ines Sarti Pascoal (Portugal) and Anamarija Pinter (Croatia)